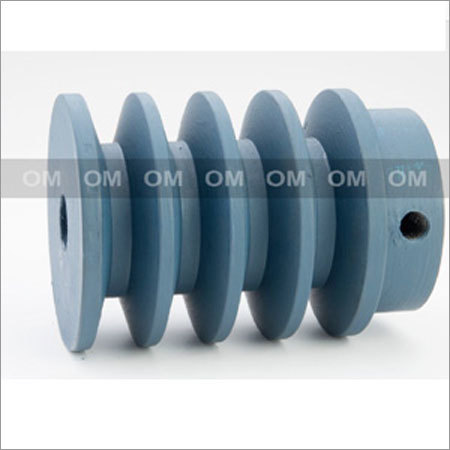

Industrial iron Pulleys

Price 250 INR/ Piece

Industrial iron Pulleys Specification

- Number Of Grooves

- Single/Multiple (Available)

- Mounting Type

- Fixed

- Application

- Material Handling, Lifting, Conveyor Systems

- Bearing Type

- Ball Bearing

- Pulley Type

- Industrial V-Belt Pulley

- Diameter

- 200 mm to 1200 mm

- Load Capacity

- Up to 5 Tons

- Lifting Height

- Up to 10 meters

- Bore

- Customizable as per requirement

- Sling Type

- Compatible with Wire Rope & Chain

- Chain Length

- As per application

- Features

- Rust resistant, High strength, Precision engineered, Durable finish

- Power Source

- Manual or Motor Driven

- Material

- Cast Iron

Industrial iron Pulleys Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

About Industrial iron Pulleys

Precision-Engineered for Industrial Excellence

Each pulley is manufactured with meticulous attention to balance and durability, guaranteeing smooth operation for material handling, lifting, and conveyor applications. The dynamic balancing ensures minimal vibration and longer lifespan, making them ideal for industries requiring consistent performance and safety.

Customizable to Suit Varied Applications

Our industrial pulleys offer extensive customization options. From groove section selection to bore size and hub type (solid or split), each pulley can be tailored to specific operational requirements. Color, surface finish, and number of grooves can be personalized, ensuring seamless integration into new or existing systems.

Designed for Harsh Work Environments

Constructed from robust cast iron and treated with rust-resistant coatings, these pulleys withstand exposure to challenging environmental conditions and temperature extremes. Their high strength and precision engineering enable effective performance even under heavy loads and continuous use, making them a reliable choice for industrial operations.

FAQs of Industrial iron Pulleys:

Q: How are the grooves and bore size of the pulley customized?

A: Groove sections (A, B, C, D, SPA, SPB, SPC) and bore size are tailored to customer requirements based on provided drawings or specifications. This ensures compatibility with your machinery and optimal performance in your specific application.Q: What benefits does the powder-coated or painted finish provide?

A: The powder-coated or painted finish enhances corrosion resistance, extends the lifespan of the pulley, and provides a durable, aesthetically pleasing surface that withstands harsh working conditions in industrial settings.Q: When should I choose a solid hub versus a split hub design?

A: Solid hubs are ideal for permanent installations requiring strong, fixed support. Split hubs are recommended when ease of installation, removal, or adjustment is necessary, especially in environments where quick maintenance is important.Q: Where can these industrial pulleys be used?

A: These pulleys are widely applied in material handling systems, lifting mechanisms, conveyor systems, and similar industrial setups where reliable power transmission and load-bearing are required.Q: What is the process for ordering customized pulleys?

A: To order, provide your specific requirements, such as groove type, bore size, diameter, hub type, and any special features or finishes. Our engineering team will review the details and manufacture the pulleys according to your precise needs and drawings.Q: How does dynamic balancing improve pulley performance?

A: Dynamic balancing significantly reduces vibration during operation, leading to quieter performance, less wear on components, and an extended service life for both the pulley and associated machinery.Q: What are the advantages of using these iron pulleys in heavy-duty industrial applications?

A: Our pulleys offer rust resistance, high strength, precision engineering, and durability. They are suited for heavy loads up to 5 tons and work efficiently across a broad temperature range, providing reliable performance and reducing maintenance downtime.

More Products in Solid Pulley Category

Industrial Pulley 4x4xc

Price 600 INR / Piece

Minimum Order Quantity : 10 Pieces

Bore : Other, Standard Bore

Power Source : Manual

Features : Corrosion Resistant, High Strength Construction

Mounting Type : Fixed

Hard Steel Solid Pulley

Price 550 INR / Piece

Minimum Order Quantity : 10 Pieces

Bore : Other, Precise Machined Bore

Power Source : Manual / Mechanical Drive

Features : Corrosion Resistant, Precision Engineered, Durable Finish

Mounting Type : Fixed Mounting

Industrial Drum Pulley

Price 150 INR / Piece

Minimum Order Quantity : 10 Pieces

Bore : Other, Custom sizes available

Power Source : Manual or Motor Driven

Features : Corrosion resistant, high durability, precision engineered

Mounting Type : Foot Mounted

Conveyor Pulley

Price 250 INR / Piece

Minimum Order Quantity : 10 Pieces

Bore : Other, Customizable as per requirement

Power Source : Mechanical (Driven by Conveyor)

Features : Highly Durable, Corrosion Resistant, Precision Balanced, Easy Maintenance

Mounting Type : Flange Mounted

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS