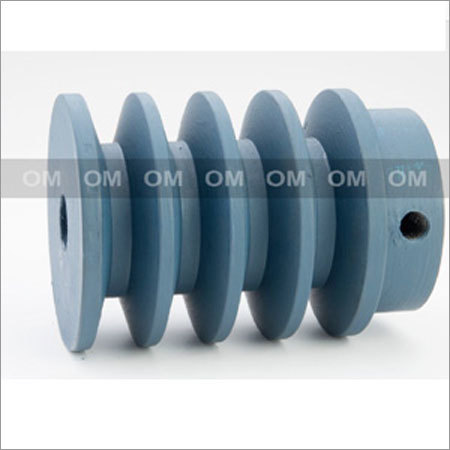

Conveyor Pulley

Price 250 INR/ Piece

Conveyor Pulley Specification

- Power Source

- Mechanical (Driven by Conveyor)

- Application

- Conveyor Systems, Bulk Material Handling

- Diameter

- 150 mm – 1200 mm

- Bearing Type

- Spherical Roller Bearing

- Bore

- Customizable as per requirement

- Features

- Highly Durable, Corrosion Resistant, Precision Balanced, Easy Maintenance

- Load Capacity

- Up to 60 Tons

- Mounting Type

- Flange Mounted

- Number Of Grooves

- Plain/Single Groove (customized options available)

- Pulley Type

- Head, Tail, Bend, Snub Pulley

- Material

- Mild Steel

Conveyor Pulley Trade Information

- Minimum Order Quantity

- 10 Pieces

- FOB Port

- Rajkot , Gujarat

- Supply Ability

- 7 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

- Certifications

- ISO 9001: 2008

About Conveyor Pulley

Versatile Performance for Conveyor Systems

Designed for a wide range of conveyor applications, our pulleys offer a customizable solution for head, tail, bend, and snub requirements. The durable construction and precision engineering ensure reliability in bulk material handling, regardless of the environment or material being transported.

Quality Materials and Advanced Finish Options

Each pulley uses mild steel with premium shaft options in EN8 or EN9 equivalents, providing strength and resilience. Surface finishes include lagged (rubber/polyurethane) or bare, accommodating operational preferences and enhancing longevity, grip, and corrosion resistance.

Precision Engineering and Customization

Our pulleys undergo dynamic and static balancing to promote low vibration and extended bearing life. With flexibility in bore size, groove design, and color, we offer tailored solutions that seamlessly fit diverse client specifications and industry standards, including IS 8531.

FAQs of Conveyor Pulley:

Q: How are the conveyor pulleys balanced for optimal operation?

A: Our conveyor pulleys are subject to both dynamic and static balancing, significantly reducing vibration during operation and resulting in smoother performance and extended bearing service life.Q: What customization options are available for these pulleys?

A: We offer customization in face width, diameter, bore size, surface finish (lagged or bare), mounting type, groove configuration, color, and even adherence to specific standards or client drawings to ensure compatibility with your conveyor system.Q: What are the primary applications for these conveyor pulleys?

A: These pulleys are widely utilized in bulk material handling and conveyor systems, serving roles such as head, tail, bend, and snub pulleys in industries like mining, manufacturing, power plants, and other heavy-duty sectors.Q: Which materials are used for the pulley shafts, and why?

A: The shafts are crafted from EN8 or EN9 steel, or equivalent materials, chosen for their high tensile strength and wear resistance, which ensures the pulleys durability under heavy load conditions.Q: When should I choose a lagged (rubber/polyurethane) surface over a bare finish?

A: Lagged surfaces provide enhanced grip, reduce slippage, and help protect the pulley and belt from wear in demanding environments. Bare finishes are preferred for applications requiring minimal resistance or where lagging is not necessary.Q: What packaging options are provided for shipping?

A: Depending on quantity and client preference, pulleys are packaged either loose or securely in wooden boxes to ensure safe transportation and delivery, whether for domestic or export shipments.

More Products in Solid Pulley Category

Industrial iron Pulleys

Price 250 INR / Piece

Minimum Order Quantity : 10 Pieces

Number Of Grooves : Single/Multiple (Available)

Bearing Type : Ball Bearing

Mounting Type : Fixed

Diameter : 200 mm to 1200 mm

Industrial Pulley 4x4xc

Price 600 INR / Piece

Minimum Order Quantity : 10 Pieces

Number Of Grooves : 4

Bearing Type : Sealed Ball Bearing

Mounting Type : Fixed

Diameter : 4 Inch

Industrial Pulley 3.5X2XB

Price 240 INR / Piece

Minimum Order Quantity : 10 Pieces

Number Of Grooves : 2

Bearing Type : Without Bearing

Mounting Type : Fixed

Diameter : 3.5 Inch

Hard Steel Solid Pulley

Price 550 INR / Piece

Minimum Order Quantity : 10 Pieces

Number Of Grooves : Single / Multiple

Bearing Type : Sealed Ball Bearing

Mounting Type : Fixed Mounting

Diameter : Up to 400 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS