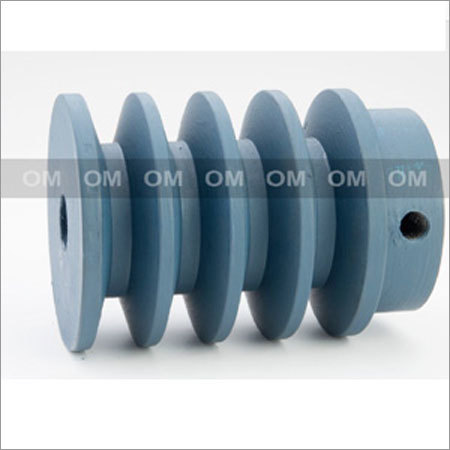

Industrial Drum Pulley

Price 150 INR/ Piece

Industrial Drum Pulley Specification

- Load Capacity

- Up to 10 Ton

- Features

- Corrosion resistant, high durability, precision engineered

- Number Of Grooves

- Single or Multiple

- Pulley Type

- Drum Pulley

- Mounting Type

- Foot Mounted

- Power Source

- Manual or Motor Driven

- Application

- Industrial conveyor systems, mining, material handling

- Bearing Type

- Roller Bearing

- Bore

- Custom sizes available

- Diameter

- 100 mm to 1200 mm

- Material

- Mild Steel

Industrial Drum Pulley Trade Information

- Minimum Order Quantity

- 10 Pieces

- FOB Port

- Rajkot , Gujarat

- Supply Ability

- 7 Pieces Per Day

- Delivery Time

- 1 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

- Certifications

- ISO 9001: 2008

About Industrial Drum Pulley

These pulleys are used for the vertical lifting of materials with conveyor belt such as coffee, rice, food grains and other granular materials. We are the reliable manufacturer and supplier of a comprehensive range of Drum Pulleys. These are made of premium quality iron and steel and provide long service life.Precision Engineering for Peak Performance

Each drum pulley is precision-engineered using advanced manufacturing techniques, ensuring a high degree of accuracy and durability. The use of EN8/EN9 steel shafts combined with high-quality roller bearings guarantees smooth operation and long service life, even under heavy loads and continuous usage.

Versatile Applications and Customization

These pulleys are suitable for a broad range of applications, from industrial conveyor systems to mining and material handling operations. With customizable face widths, diameters, and bore sizes, they can be tailored to meet your specific operational needs and installation requirements.

Adherence to International Standards

Our drum pulleys are manufactured in compliance with IS, CEMA, and DIN standards, ensuring consistent quality and performance. The use of corrosion-resistant materials and robust finishes further enhance their longevity, making them a reliable choice for harsh industrial environments.

FAQs of Industrial Drum Pulley:

Q: How are these drum pulleys maintained in industrial applications?

A: These drum pulleys require minimal maintenance due to their robust construction with mild steel and corrosion-resistant finishes. Regular inspections for wear, proper lubrication of roller bearings, and cleaning are sufficient to ensure long-term, trouble-free operation.Q: What makes EN8/EN9 steel suitable for pulley shafts?

A: EN8/EN9 steel is chosen for its excellent strength, machinability, and resistance to fatigue, making it ideal for shafts that must handle heavy loads and the demands of continuous industrial operation.Q: When should static or dynamic balancing be chosen for drum pulleys?

A: Static balancing is suitable for slower or less critical applications, while dynamic balancing is recommended for high-speed conveyor systems where vibration control and precision are essential for smooth operation and extended component life.Q: Where can these industrial drum pulleys be utilized?

A: These pulleys are deployed in a variety of industrial settings, including conveyor systems in manufacturing plants, mining operations, and material handling facilities, where durability and reliable performance are paramount.Q: What is the process for customizing the bore size and face width?

A: Custom bore sizes and face widths are available based on customer specifications. The process involves evaluating your applications requirements, followed by precision machining to achieve the exact dimensions needed for seamless integration into your system.Q: How does the powder-coated or painted finish benefit the drum pulley?

A: A powder-coated or painted surface finish significantly enhances the pulleys resistance to corrosion and surface wear, prolonging its service life and maintaining its appearance in harsh industrial environments.Q: What are the key benefits of using these drum pulleys in conveyor systems?

A: Key benefits include high load capacity (up to 10 tons), exceptional durability, precision engineering, low maintenance requirements, and compliance with recognized industrial standards, resulting in decreased downtime and increased productivity.

More Products in Solid Pulley Category

Industrial iron Pulleys

Price 250 INR / Piece

Minimum Order Quantity : 10 Pieces

Mounting Type : Fixed

Power Source : Manual or Motor Driven

Features : Rust resistant, High strength, Precision engineered, Durable finish

Load Capacity : Up to 5 Tons

Industrial Pulley 3.5X2XB

Price 240 INR / Piece

Minimum Order Quantity : 10 Pieces

Mounting Type : Fixed

Power Source : Manual

Features : Corrosion Resistant, Durable, Precision Machined

Load Capacity : Depend on Application

Industrial Pulley 4x4xc

Price 600 INR / Piece

Minimum Order Quantity : 10 Pieces

Mounting Type : Fixed

Power Source : Manual

Features : Corrosion Resistant, High Strength Construction

Load Capacity : Heavy Duty

Hard Steel Solid Pulley

Price 550 INR / Piece

Minimum Order Quantity : 10 Pieces

Mounting Type : Fixed Mounting

Power Source : Manual / Mechanical Drive

Features : Corrosion Resistant, Precision Engineered, Durable Finish

Load Capacity : Heavy Duty (up to 5 Ton)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS